Components should withstand extreme loads, have a long service life and meet economic criteria. Where the optimal shape of the parts is limited by conventional production methods such as turning, milling or injection molding, additive manufacturing offers a remedy. With a topology optimization, components can be produced in exactly the desired shape in 3D printing, in a way that would never have been possible with conventional methods. Where previously an elaborate assembly had to be designed and each part required considerable design effort, today this assembly can be manufactured as a single component using the additive manufacturing process → One drawing, one time data acquisition and maximum flexibility in the event of changes!

With the challenge of making racing cars ever faster - lighter and more reliable - Sauber Engineering was born: the company that specializes in the development of innovative methods and the production of high-quality components that did not exist before. Sauber Engineering has the mandate and the freedom to go to the limit - to explore where the limits are. We have know-how and infrastructures that customers from a wide variety of industries benefit from, both in overarching technology development and in practical fields of application such as additive manufacturing and vehicle development.

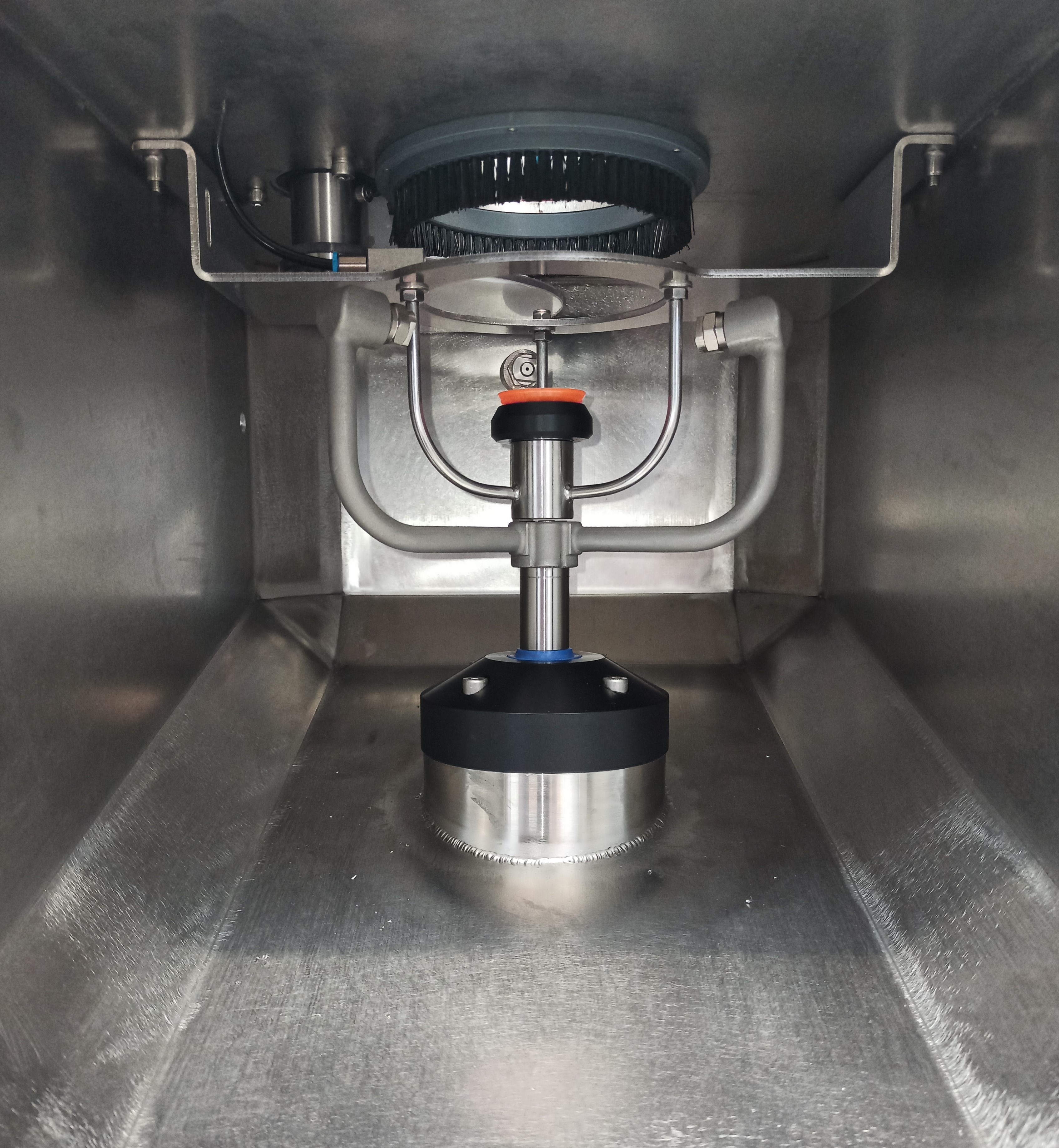

Since the company was founded, OptoTech has set standards in the field of machines and processes for the precision optics industry. Each optic has its own challenge and requires an individual perspective on production. A wide variety of materials, geometries and tolerances require a large number of machines. Today OptoTech has the largest range of machines and processes for processing precision optics worldwide. In order to be able to automatically and economically remove the protective film on the lens blanks, the company Optotech has an innovative idea: A spray chamber should be there with the help of water under a certain pressure in order to remove the protective film without wear during the process of processing eyeglass lenses. A special triple spray head was developed for this purpose. The rotation and the flow of water pushed through the nozzles detach the protective film from the glass within seconds: “A simple part with a great effect”.

A logistical nightmare for manufacturing. Even if Optotech can order the part from a single source, the supplier incurs considerable costs for activities such as welding operations or tube bending. In addition, the supplier bears the entire risk. If Optotech orders the individual parts themselves and then has them processed into one part, the administrative and operating costs drive up the price of this spray head massively. If there is a change to the assembly, it will be very cumbersome to make the adjustments. The geometrical determinations are also not ideal. Due to the manufacturing process, the water flow through 90 degree angles is suboptimal.

Together with the company Sauber Engineering, the spray head was designed as a 3D printed part and then manufactured in the Sauber Hinwil halls:

Individual, non-printable areas, such as threads or a seat for an O-ring seal, have been reworked. The surface finish gives the component the necessary qualitative touch.

Now the installation at Optotech already followed:

Despite the special application with a medium and under high pressure, the 3D printed part has been successfully tested and has already been delivered to customers.

We are proud that we were able to make the high-quality, future-oriented technology of additive manufacturing increasingly known in the mechanical engineering industry. Optotech is also looking forward to equipping its machines with parts from technology leaders in the future. So we are going full throttle into the future together. You too can benefit from the added value of 3D printing.

Now start your project too! We look forward to your ideas and inquiries. Tell us about it. Simply use the contact options below and tell us briefly or in detail what you have in mind. Of course, your ideas and inquiries are in safe hands with us. If you wish, we can also sign NDAs for you.