What's next? Industry 4.0 is not on our doorstep, no, the fourth industrial revolution is omnipresent. New technologies from digitization enable strategic further developments. The big problem is that companies cannot use a standardized flowchart for implementing these technologies. Every customer is individual, every customer has different needs and every customer is equipped differently. For a successful implementation, the customer's needs must be fully addressed already during initial contacts. The product of the solution is the result of joint cooperation.

For customer and manufacturer it is important to have an even higher planning reliability of the costs. It is the strategic handling of data that separates winners and losers in the race for market leadership (Prof. Dr. Kagermann et al., 2018). Business drivers in the field of Industrie 4.0 are individualization and self-control.

With PCam's new and innovative concepts, we automate your processes. CAD / CAM / automation systems nowadays represent one of the most important components of industrial manufacturing. These tools are developed by the Swiss company PCam to enable the customer an efficient 24/7 production. Through flexible and customer-oriented needs analysis, individual, specific solutions can be developed, no matter what machine you are working with. The USP of PCam is undeniable: Individual solutions for individual customers exactly according to their needs for maximum success!

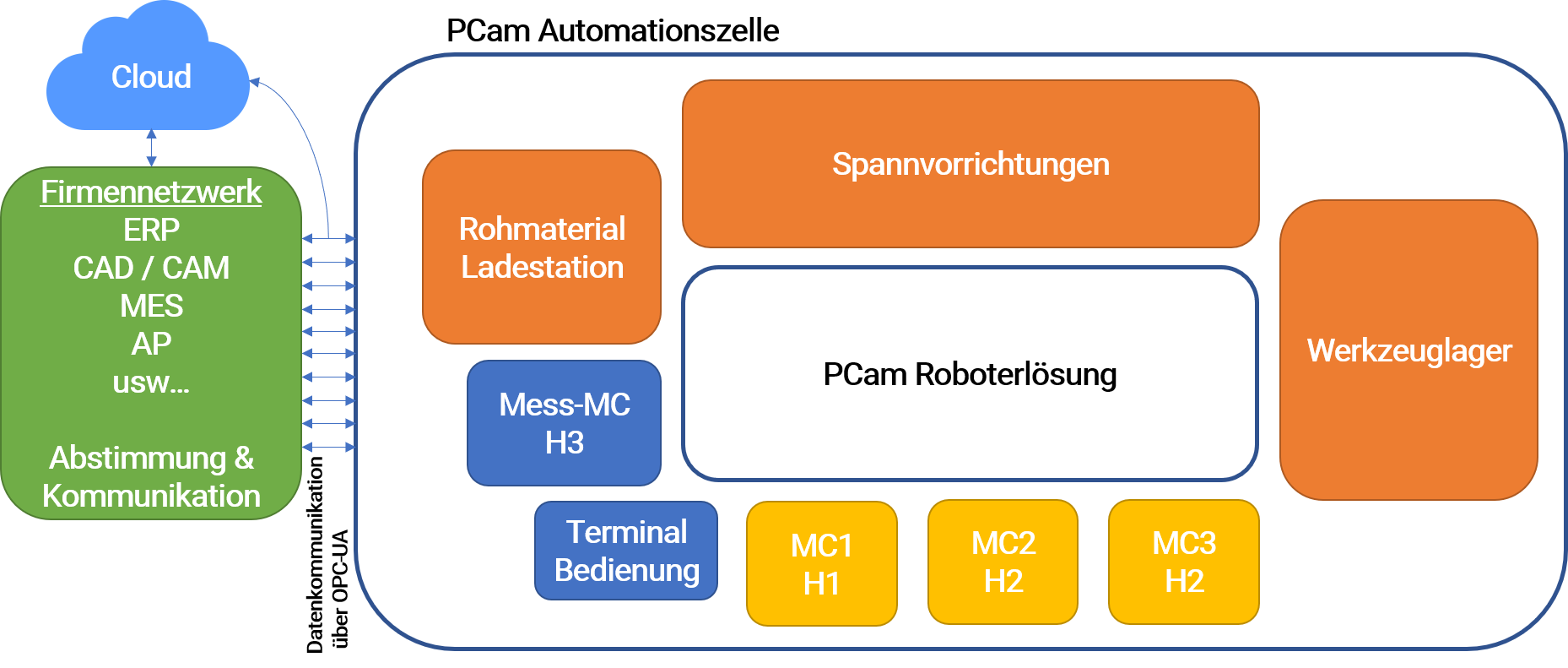

PCam's part handling solutions are based on industrial robots with a wide range of potential for automating metal-cutting machine tools or EDM machines - whether new or existing machines. Depending on the requirements, we automate single machine tools up to complex production lines. From PCam you get an efficient and process-safe solution, regardless of batch size and part spectrum. In addition, processes such as deburring, washing, tool management, fixture management, marking and 3D measuring can be easily integrated into the automation. And thanks to the powerful software, there are no limits to the connection to other interfaces such as ERP, MES, tool management, etc. PCam automates your processes!

The resulting added value cannot be ignored:

- A much higher utilization of the machines is possible

- Fault management reduces downtimes

- Increase in process reliability

- Increase in economic efficiency

- Running unmanned shifts more effectively

We are convinced that people make the difference, because limits only exist in our imagination!

Make an appointment, we will be happy to advise you and increase your productivity!

Your Sales4b2b Team!