For the demanding toolmaker

Swiss companies in tool and mould making are among the world's leading manufacturers. They are characterised by innovative solutions and the highest quality. They supply demanding customers from the medical technology, food and packaging industries as well as from the automotive industry, the watch industry and various other industrial sectors. Here we have an integrated package of HSC and EDM machine tools from exeron. Automated with the innovative and forward-looking solutions from PCam, these machines provide you with efficient, economical and flexible production of individual and small series with the highest precision and surface quality.

For efficient and flexible large-scale series production

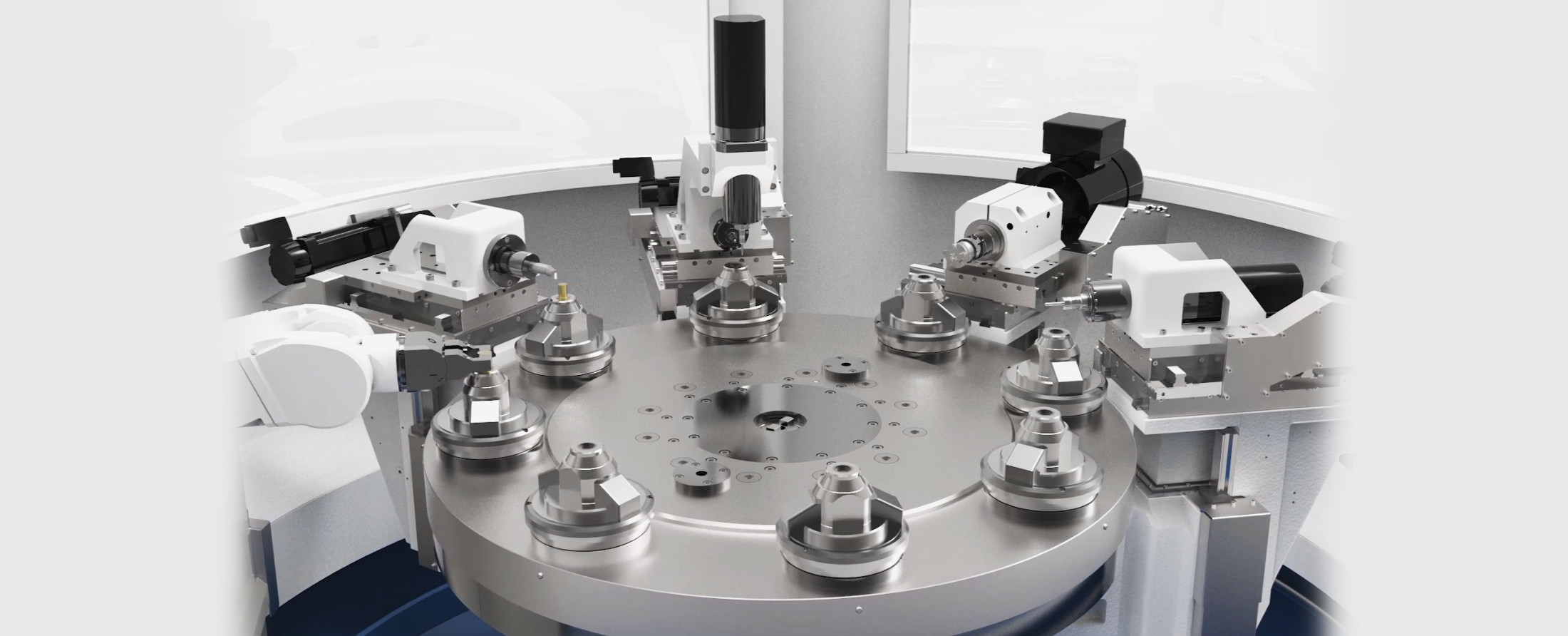

After more than 75 years, Imoberdorf's concerns remain the same: to use, develop and integrate the best technological solutions to produce highly productive "Swiss Made" machines that are among the most precise in the world. To respond to your evolving needs in an ever-changing market, we know how to innovate, surprise and exceed your expectations. At imoberdorf, our solutions stand for flexibility, reliability, durability, speed and precision. Every design meets your exact requirements and offers you a turnkey solution. You benefit from our know-how.

Due to the almost unlimited application possibilities, imoberdorf rotary transfer systems are used in a wide variety of industries such as the watchmaking and automotive supply industries or the medical sector.

exeron

HSC and EDM, both better, better both.

There are things that are simply better together than separately. Milling and EDM, for example. So it's good to know that exeron offers you both in the highest quality. So you have a holistically thinking partner for HSC milling and EDM erosion. The machine tool manufacturer also offers automated system solutions. exeron: experts in EDM + HSC.

HSC:

Whether three-axis or five-axis machining, small individual pieces or large-scale production: Our HSC milling machines are always compact, economical to purchase and machine, highly precise as well as versatile. The most important factors for our machine tools are economy, sustainability and quality - for our customers. Because exeron has more than 20 years of experience as an HSC machine manufacturer and has more than 600 high-speed milling machines in operation worldwide. We are a system provider. Starting with complete HSC centres, tool holding and CAD/CAM systems as well as handling devices, we also provide you with all the necessary services for high-speed cutting - you can rely on us.

EDM die-sinking; EDM technology with customer benefits

Our decades of experience as a pioneer in EDM have made exeron an internationally recognised EDM machine manufacturer. exeron's technology is geared solely to your needs. As a machine tool manufacturer, exeron ensures your profitability, the sustainability of your investment and your quality - with our EDM technology. "Made in Germany". Directly in your company and with services that make you truly successful through maximum effectiveness. You can rely on that.

PCam

Automation

With a group of automation specialists with years of practical experience in this field, it develops specific and efficient solutions for its customers. Depending on the quantities to be assembled, such systems essentially differ in their degree of automation. This is determined together with the customer in order to identify the most efficient and cost-effective solution for the respective application. Many years of experience in this field and the ability to design and manufacture the parts required for an automation solution in-house result in cost-effective systems that are precisely adapted to the customer's needs with short delivery times.

PCam and Industry 4.0

With Industry 4.0, a fundamental change is taking place in industry. Production is becoming more one-piece, faster and more flexible. Industry standards, on the basis of which components, machines and systems communicate reliably and securely with each other, are indispensable for the successful implementation of Industrie 4.0.

Highly integrated systems in the form of automation and production cells that significantly increase competitiveness are in vogue. PCam offers various hardware and software solutions that significantly increase the degree of automation and networking in production and across the entire value chain, thus enabling more economical production in the DACH region.

Imoberdorf

At the centre of every rotary transfer machine manufactured by Imoberdorf is the customer's requirement. You specify the desired parameters in terms of precision, flexibility and productivity, and everything else is handled by Imoberdorf.

Our expertise covers all steps from conception and implementation to the manufacture and commissioning of your rotary transfer machine. You receive a complete solution from a single source.

Imoberdorf stands for durable, high-quality metal-cutting systems that produce high-quality small and very small parts in large quantities with extreme precision and speed. The demand for perfection is reflected in all Imoberdorf products and services. Produce more economically than ever before...

Specifications Exeron, PCam and Imoberdorf machines

- Versatile, extremely precise and highly efficient

- Holistic active temperature control

- High-quality interior design in stainless steel

- Large distance between spindle nose and table as well as generous Z-traverse path

- Spindle speed 42`000 / min.

- Internal spindle length sensor

- Rapid traverse XxYxZ 40m/min.

- Tool magazine 30/60/90 HSK E-40

- Haidenhain TNC 640 CNC control

- Linear direct drives

- Covered laser measuring system

- Workpiece weight with five axes 60 kg with three axes 550kg

- Preparation for automation

- Reliable and durable

- Holistic active temperature control

- High-quality interior design in stainless steel

- Large distance between spindle nose and table as well as generous Z-traverse path

- Spindle speed 42`000/min. HSK-E40; 36`000/min. with HSK-E50

- Internal spindle length sensor

- Rapid traverse XxYxZ 60m/min.

- Travel XxYxZ 955x625x400mm

- Tool magazine 30/60/907120 HSK E-40; 27/54/81/108 HSK-E50

- Haidenhain TNC 640 CNC control

- Linear direct drives

- Laser measuring system outside the working area

- Workpiece weight max 250 kg

- Preparation for tool and workpiece automationFlexible, precise and efficient

- Large, economical and durable

- Holistic active temperature control

- High-quality interior design in stainless steel

- Large distance between spindle nose and table as well as generous Z-traverse path

- Spindle speed 42`000/min. HSK-E40; 36`000/min. with HSK-E50/HSK-F63

- Internal spindle length sensor

- Rapid traverse XxYxZ 80m/min.

- Travel XxYxZ 1055x760x540mm

- Tool magazine max 210 HSK-E40; 189 HSK-E50 and 154 HSK-F63

- Haidenhain TNC 640 CNC control

- Linear direct drives

- Laser measuring system outside the working area

- Workpiece weight five-axis max 350 kg, three-axis max 1`000kg.

- Preparation for tool and workpiece automation

- Design for minimum quantity lubrication, dry, cutting oil and wet machining

- Compact, highly precise and versatile

- High rigidity design for optimum machine dynamics, high precision and perfect tool quality

- Large distance between spindle nose and table as well as generous Z-traverse path

- Spindle speed 42`000/min. HSK-E40;

- Internal spindle length sensor

- Rapid traverse XxYxZ 30m/min.

- Travel XxYxZ 515x340x355mm

- Tool magazine 16/40 HSK-E40

- Haidenhain TNC 640 CNC control

- Direct path measuring system resolution 0.01ym.

- Workpiece weight five-axis max 12 kg, three-axis max 500kg.

- Preparation for tool and workpiece automation

- Space-saving, dynamic and universal

- Optimised working space for five-axis machining

- Large distance between spindle nose and table as well as generous Z-traverse path

- Spindle speed 42`000/min. HSK-E40; 36`000/min. with HSK-E50/HSK-F63

- Internal spindle length sensor

- Rapid traverse XxYxZ 50m/min.

- Travel XxYxZ 650x550x400mm

- Tool magazine 30/60/90 HSK-E40; 27/54/81 HSK-E50

- Haidenhain TNC 640 CNC control

- Direct path measuring systems Resolution 0.01ym.

- Workpiece weight five-axis max 200 kg, three-axis max 600kg

- Preparation for tool and workpiece automation

- Design for minimum quantity lubrication, dry, cutting oil and wet machining

- Space-saving, integrated and highly dynamic

- Developed for microerosion in electronics and medical technology

- Highest stability due to FEM-optimised undivided machine base made of mineral casting

- Digital AC servo direct drives and glass scales for highest traverse and control dynamics

- Generator current 60A

- Travel XxYxZ EDM310 350x270x270; EDM 312 450x300x300mm

- Electrode weight EDM 310 25kg; EDM 312 30/150kg.

- Fully simultaneous CNC contouring control MF30 based on Windows operating system

- High Power generator technology from exeron

- Workpiece weight max EDM 310 500kg; EDM 312 800kg.

- Preparation for tool and workpiece automation

- Compact, fast, highly stable and powerful

- Highest stability due to FEM-optimised undivided machine base made of mineral casting

- Digital AC servo direct drives and glass scales for highest travel and control dynamics

- Generator current 60A / 120A

- Travel XxYxZ EDM313 620x420x400mm; EDM 314 900x700x450mm

- Electrode weight EDM 313 50/250kg; EDM 314 50/500kg.

- Fully simultaneous CNC contouring control MF30 based on Windows operating system

- High Power generator technology from exeron

- Workpiece weight max EDM 313 1500kg; EDM 314 3000kg

- Lowerable, filled movable container for free access to the workpiece and short filling and emptying times

- Preparation for tool and workpiece automation

- Huge, strong, ergonomic

- Highest stability due to FEM-optimised undivided machine base basket made of mineral casting

- Integrated dielectric system with automatic cooling for constant working conditions (optional: backflush filter)

- Digital AC servo direct drives and glass scales for maximum travel and control dynamics

- Generator current 60A / 120A

- Travel XxYxZ EDM316 1500x1180x800mm; EDM 316XXL 2000x1180x800mm

- Electrode weight EDM 316 50/500kg; EDM 316XXL 50/500kg.

- Fully simultaneous CNC contouring control MF30 based on Windows operating system

- High power generator technology from exeron

- Workpiece weight max EDM 316 8000kg; EDM 316XXL 8000kg

- Lowerable, filled movable container for free access to the workpiece and short filling and emptying times

- Preparation for tool and workpiece automation

- PCamMES is an MES (Manufacturing Execution System) specifically designed for the precision engineering, tooling, injection moulding, stamping and extrusion industries. PCamMES communicates data with your ERP system.

- PCamPPS (PDC) allows you to manage a planning model for the mould making process and develop knowledge bases to support planning.

- PCamMonitor (MDE) provides remote and real-time monitoring of the status of any connected CNC machine.

- PCamIoT Internet of Things, enables everything to be monitored.

- PCamTM PCamToolManager

- PCamCell

- PCamJM PCamJobManager

- PCamERP

- Industry 3-4.0

- PCamRoboCube: Automated handling robot for pallets and tools for up to 3 CNC machines. Application for milling, wire-cutting and die-sinking EDM, turning, grinding and measuring machines. Machine networking: master or serial or tcp/ip. Data Matrix Code or RFID identification of parts and tools.

- Maximum dimensions W x L x H (m): 2.5 x 2.2 x 2.7.

- System weight (kg): 2'300.

- Maximum extension (mm): 1'200.

- Maximum mobile weight up to (kg): 150 at wrist.

- Maximum pallet size (mm): 320 x 320 x 230 pallet + workpiece.

- Maximum number of pallet spaces: 30.

- Maximum tool weight (kg): 5.

- Maximum tool size (mm): 85 x 85 x 250 collet + tool.

- Number of tool positions: 200.

- Power supply: 3 x 400V + PE.

- Pneumatic supply: 200 l/min at 7 bar minimum.

PCamGantry

Extremely stable gantry (7th axis). Allows highly dynamic axis movements with maximum weight load.

Guides are mounted on the gantry that allow the robot to move along the horizontal axis of the structure.

The peculiarity of this solution is that the trolley on which the robot is placed can be controlled directly from the keyboard of the robot itself and practically becomes the seventh axis that the operator can easily control, as the programming language for the robot is the same.

The system as a whole is relatively quick and easy to configure and set up according to the customer's needs . It is enough to dimension the structure and the guides based on the characteristics of the robot itself and then with the adaptation of the layout and the grippers of the pallet gripping.

The mechanical layout is thus reduced to a minimum, as is the definition time and thus the start of construction of the system. This is because the components and modules used are all standard products.

The imo-flex* rearranges proven kinematics. The manageable one for smaller batch sizes with up to 80 tools!

The tool changer makes up to 10 tools per machining unit available very quickly. Optionally, the system can also be supplemented with a tool magazine with 50 tools. This can ensure chaotic production or keep sister tools ready for "ghost shifts".

The layout and interfaces of the imo-flex are designed in such a way that several machines can be flexibly linked together. Additional units or loading and unloading robots can be used several times. Ecology-oriented production can thus be lived!

TECHNICAL DATA:

- Number of units: up to 3 machining units

- Number of main spindles: up to 3 spindles (HSK-25 to HSK-63)

- Positioning accuracy: - Swivel table ± 1 µm

- Number of tools: - Tool changer - Tool magazine 10 pcs. 50 pcs. (optional) Loading/unloading: of the workpiece carriers automatically

- Tool change time: < 1.5 sec. Workpiece size: up to approx. 150 x 150 x 150 mm

- Dimensions: 3'000 x 2'400, height 2'200 mm

On an area of only 9 square metres and a height of 2.30 metres, the imo-compact combines a complete, highly productive rotary transfer system: The imo-compact controls 4 to 8 machining stations with up to 14 spindles via CNC. Parts can be fed from the bar, by load handling, robot or manually.

The imo-smart is a highly flexible, versatile rotary transfer system. 4 to 16 machining stations with up to 22 or more spindles ensure the fastest set-up times. With the imo-smart, you have a machining production solution with a wide range of applications adapted to your needs. Parts are fed from the bar, by load handling, robot or manually. The imo-smart is designed as an extremely flexible and versatile solution. The excellent accessibility allows adjustments to be made in record time.

The repeatability of both machines is ± 0.003 millimetres, making the imo-compact and imo-smart among the world's most precise rotary transfer machines.

In terms of productivity and functional possibilities, the imo-space is Imoberdorf's largest rotary transfer machine. Designed for 6 to 20 machining stations with up to 45 or more spindles, the imo-space has enormous production potential.

With the imo-space, you have a chip-removing production solution with enormous chip removal capacity that is adapted to your needs.

TECHNICAL DATA

Working stroke X / Y / Z: 100 mm / 130 mm / 200 mm

Power: up to 8,5 kW

Machining repeatability: 1.5 µm and 0.5 µm with glass scale (optional)

Absolute accuracy X / Y / Z: ±1 µm / ±1 µm / ±1 µm

Available spindles: - HF up to 60'000 rpm - Multispindle - Turret - Tool changer ATC

Parts are fed from bar, load handling, robot or with pick & place. The repeat accuracy is ± 0.003 millimetres, which makes the imo-space one of the most precise rotary transfer machines in the world.

Start your project

We look forward to your ideas and inquiries. Tell us about it. Just use the contact options below and tell us in a nutshell or in detail what you imagine. Of course your ideas / inquiries are in safe hands with us. On request, we also sign NDAs.

Contact us

Newsletter

Stay up to date!